N-hance allows BP to achieve over 35,000 hours of offshore operation with no water washing

Article:

5Mins

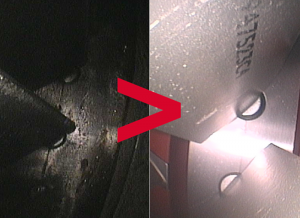

BP came to AAF for support in 2017 after poor air filtration provided by an existing high velocity bag system resulted in a catastrophic failure of GT2 on the Clair Platform. This was at a third of the design life of the engine and the root cause of the failure was inlet guide vane seizure and ultimately blade liberation.

A revolutionary new approach

BP was aware that AAF International had developed a new EPA E12 high velocity filtration solution. Critically, this could be installed within an existing high velocity housing and with no initial dP penalty. As a consequence of the gas turbine failure, BP approached AAF to determine if this new technology (N-hance® Performance Filtration) could be urgently deployed in time for the arrival of the replacement engine.

To discover how N-hance was able to provide BP with over 35,000 hours of operation offshore without water washing the engine, improved reliability, considerable cost savings and helped to increase overall offshore asset efficiency on the Clair Platform please download the full case study.