10Mins

AAF Wind Energy Overview Brochure

Wind turbines are exposed to high levels of air particulate in both onshore and offshore environments. Appropriate levels of air filtration are essential to protect capital equipment, reduce maintenance costs, and increase the life of critical components.

AAF wind turbine filters have a long filter life to reduce filter changeout, are easy to install and handle, and are designed to maximise reliability.

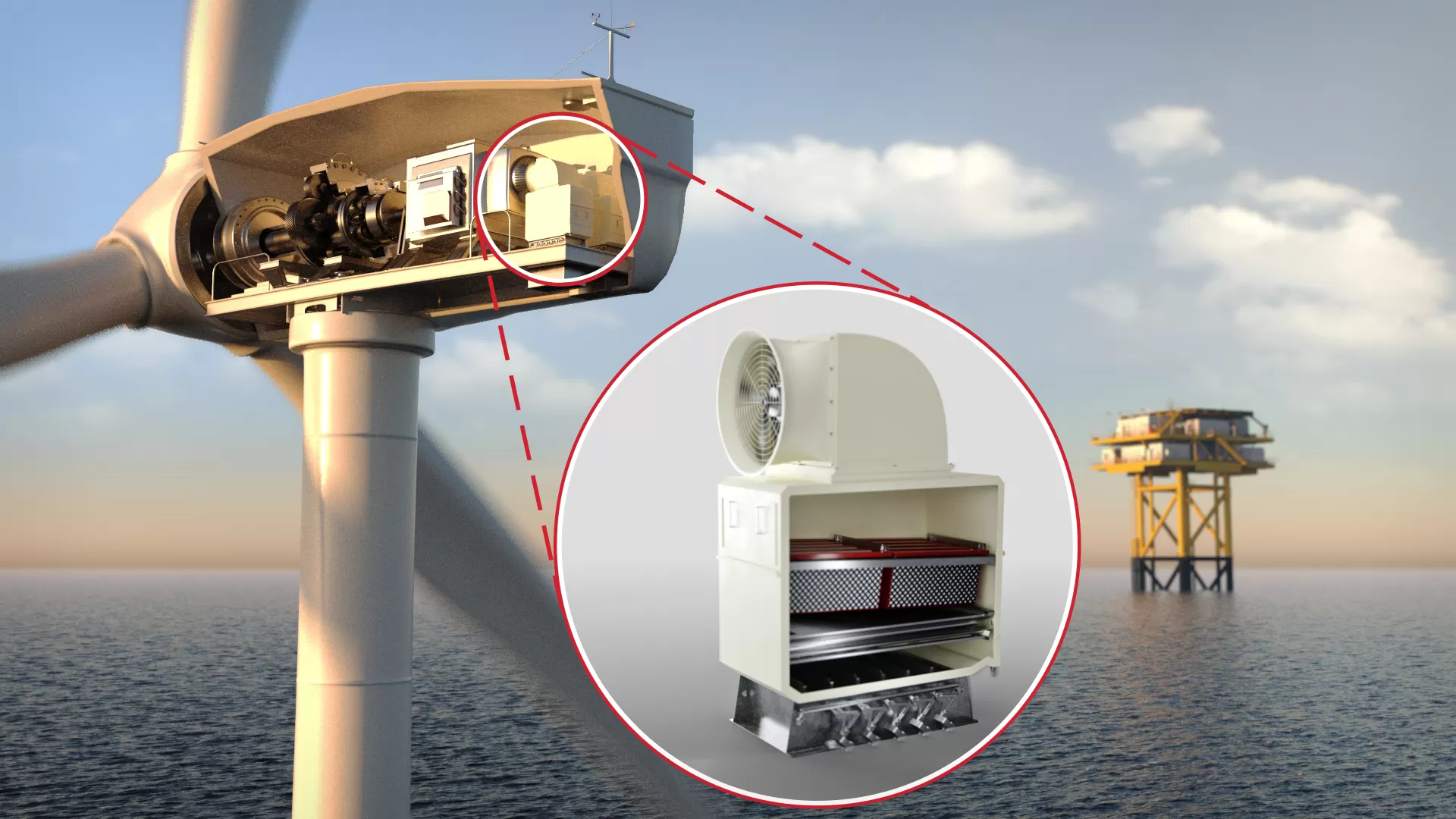

Nacelle Filtration & Ventilation Solutions

Nacelle Filtration & Ventilation Solutions

The nacelle of each wind turbine needs to be protected from air contamination to protect critical components such as the generator, gearbox, brake, and control electronics.

An air ventilation module stops equipment from overheating and ensures the area is well ventilated. Ambient air must be filtered to remove salt, moisture, dust, pollen, and hydrocarbons to protect equipment and ensure continuous operation.

Contact usWind turbine towers often require air circulation and ventilation to protect critical electronic components. AAF tower air ventilation modules circulate air in the wind turbine tower, ensuring clean filtered air is used in the air conditioning process.

Air filters are an integral component to protect the internal workings of the wind turbine. Ambient air must be filtered to remove salt, moisture, dust, pollen, and hydrocarbons to protect equipment and ensure continuous operation.

Contact usWind farms have substations located offshore to connect the energy generated by the wind turbines to the power grid. The substation is a fundamental part of any wind farm and needs to be suitably protected from the high levels of salt and moisture.

AAF, along with our parent company Daikin, can provide a full range of air filtration, heating, air ventilation, and air conditioning systems to protect critical equipment from the harsh offshore environment to ensure continuous operation and reduced maintenance costs.

Contact usAt AAF, we have dedicated products and solutions to solve specific application challenges. Product quality, reliability, and filter life are all an integral part of the design process.

Wind power turbines in offshore and coastal locations are often exposed to very harsh conditions. The air filtration challenge in these applications arrives when prevailing wind picks up sea spray laden with salt and moisture. Salt corrosion and water ingress can pose a major threat to wind turbine operational efficiency and must be avoided.

In extreme cases, exposure can result in power loss, downtime, costly repairs, and, ultimately, failure of critical components. AAF has extensive experience in offshore air filtration and can ensure risks are mitigated.

Learn moreWind power turbines onshore or inland are very exposed to different types of air quality challenges often due to their remote location. In rural settings, the wind turbine will be exposed to dust, pollen, and agricultural contamination, whereas locations nearer to industrial or urban areas are exposed to much smaller particles from hydrocarbons and other industrial pollution.

An AAF nacelle or tower air ventilation module ensures the continuous operation of the wind turbine regardless of the surrounding air contamination.

Contact us